Permanent magnet industrial large fan

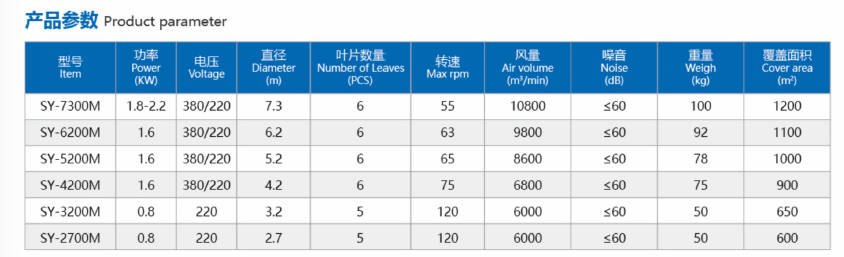

Product model:

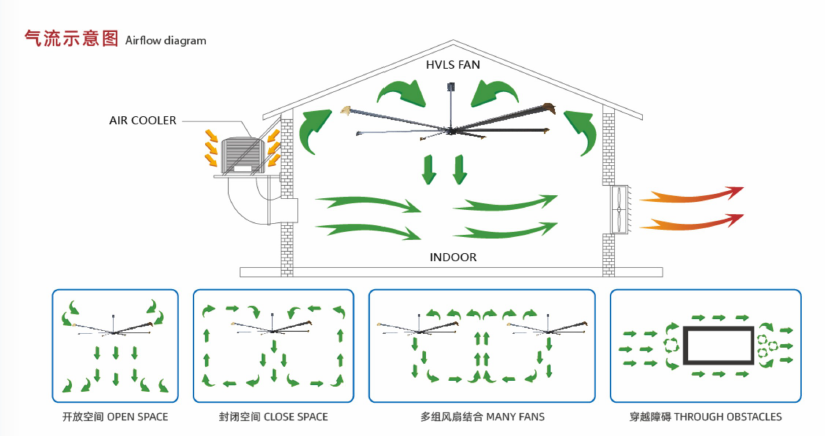

Brushless carbon, no Hall, DC drive, high torque permanent magnet brushless motor useful small size, energy saving features. Mainly used in industrial plants, logistics warehousing, public places, such as up to space.

Classification:

Key words:

Industrial electric fan

frequency

brushless

Description

Product Introduction

Brushless carbon, no Hall, DC drive, high torque permanent magnet brushless motor useful small size, energy saving features. Mainly used in industrial plants, logistics warehousing, public places, such as up to space.

FIVE INSURANCE FIVE INSURANCES

Frequency converter controller Frequency converter controller The frequency converter controller applies the principle of frequency conversion technology and microelectronics technology to control the power control equipment of the AC motor by changing the frequency of the motor's working power supply, and the frequency converter is set with an overload alarm function. In case of unknown special circumstances, the frequency converter will automatically cut off the power supply and stop running. Frequency converter controller uses the principle of frequency conversion technology and microelectronics technology to control the power control equlpment of AC motor by changing the frequency of the power supply of the motor.And the frequency converter is set with overload alarm function.in the event of unknown special circumstances,the frequency converter will automatically cut off the power supply and stop running. |  |

Upper and lower safety plate Upper and lower fuse The upper and lower fuse plates make the fan blades and the chassis connected into a whole, interconnected and mutually guaranteed. Coupling interference anti-falling device, even if the chassis screw accidentally breaks, the entire chassis falls on the anti-falling plate and cannot fall down, ensuring foolproof. The upper and lower safety pleces make the fan blade and chassls into a whole,intercon.nection and mutual protection,Coupling interference anti-drop device,even if the chassis screw breaks unexpectedly,the whole chassis can not fall down on the anti-drop plate,to ensure that nothing is wrong. |  |

Insurance Clause Article insurance Leading the use of 40CR steel material, the use of laser cutting technology to create a high-strength integral hook, effectively avoid the problems caused by low-pressure casting; And to ensure the balance and stability of the equipment when the ceiling fan lengthens the height extension rod. Leading the use of 40Cr steel,the use of laser cutting technology to create high-strength integrated bent hook,effectively avoid the problem caused by low-pressure melting casting;And ensure the balance stability of the equipment when the celling fan lengthens the height extension rod |  |

Fasteners Fasteners All fasteners are as high as grade 8.8 high-strength industrial bolts with actual stress of more than 10 times. At the same time, they are matched with Jingtuo fastening glue to ensure anti-loosening, and anti-loosening self-locking nuts and tooth-shaped anti-falling pads are installed. All fasteners are up to 8.8 grade high strength industrial bolts,the actual stress is more than 10 times,at the same time,with fine fastening glue for anti-loosening protection,and equipped with anti-loosening self-ocking nuts and toothed anti-falling pads. |  |

wire rope Wire rope The tensile strength of each wire lock can reach 1000KG, which ensures safety and can also make the fan run smoothly and increase the service life. The tensile strength of each steel wire lock can reach 1000KG,ensuring safety,but also making the fan run smoothly,increasing the service life. |  |

Factory appearance

Qualification Honor

Related Products

Gear hobbing machine

Vertical gear hobbing machine

-

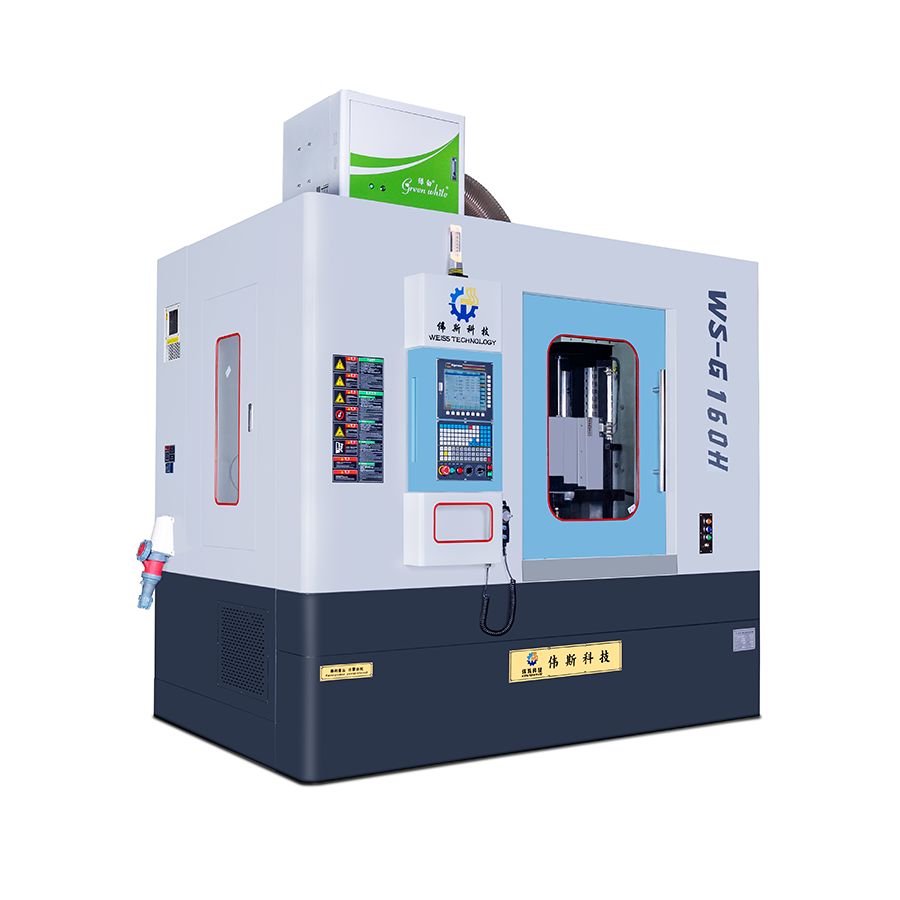

WS-G160H High-speed and efficient CNC vertical gear hobbing machine

WS-G160 high-speed and high-efficiency CNC vertical gear hobbing machine is a 6-axis 4-linkage CNC machine tool. The three numerical control linear axes are: X axis-radial feed axis; Z axis-axial feed axis; Y axis all motion axes; The three numerical control rotary axes are: C axis and worktable rotary axis; Axis B- rotary shaft of hob spindle; Axis A- frame rotary shaft. The machine tool can realize X, Z, B, C four axis linkage control.

-

WS-G260H of high speed and high efficiency direct drive CNC vertical gear hobbing machine

WS-G260H high-speed and high-efficiency direct-drive CNC vertical gear hobbing machine is a 6-axis 4-linkage CNC machine tool. The three numerical control linear axes are: X axis-radial feed axis; Z axis-axial feed axis; Y axis all motion axes; The three numerical control rotary axes are: C axis and worktable rotary axis; Axis B- rotary shaft of hob spindle; Axis A- frame rotary shaft. The machine tool can realize X, Z, B, C four axis linkage control.

-

WS-G350H of high speed and high efficiency direct drive CNC vertical gear hobbing machine

WS-G350H high-speed and high-efficiency direct-drive CNC vertical gear hobbing machine is a 6-axis 4-linkage CNC machine tool. The three numerical control linear axes are: X axis-radial feed axis; Z axis-axial feed axis; Y axis all motion axes; The three numerical control rotary axes are: C axis and worktable rotary axis; Axis B- rotary shaft of hob spindle; Axis A- frame rotary shaft. The machine tool can realize X, Z, B, C four axis linkage control.

Horizontal gear hobbing machine

-

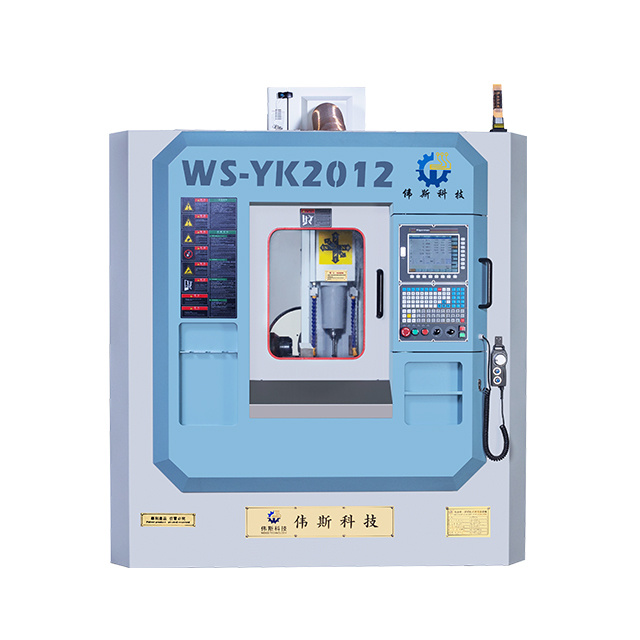

WS-YK2012 of high speed and high efficiency CNC horizontal gear hobbing machine

WS-YK2012 high-speed and high-efficiency CNC horizontal gear hobbing machine is a 7-axis 4-linkage CNC machine tool. Mainly used for shaft tooth processing, as well as high efficiency, high precision, high-volume processing of small modulus spur gears, helical gears, through numerical control technology to achieve drum gear processing and small angle cylindrical bevel gear processing, can also be used radial method of processing turbine.

-

WS-YK3016 of high speed and high efficiency CNC horizontal gear hobbing machine

WS-YK3016 high-speed and high-efficiency numerical control horizontal gear hobbing machine is a 7-axis and 4-linkage machine tool. The numerical control system uses a Higerman control system. The rotary shaft (B axis) of the cutter spindle is directly driven by a built-in direct drive motor. It is a machine tool specially developed for high-speed and high-efficiency gear high-efficiency processing. It is mainly used for processing spur cylindrical gears and helical gears with modulus m≤ 4mm, and can also be processed by radial method.

-

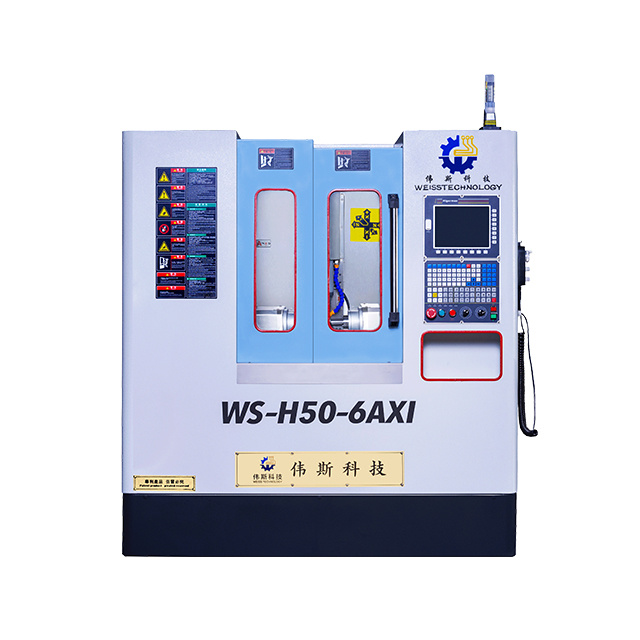

WS-H50-6AXIS of high speed and high efficiency CNC horizontal gear hobbing machine

WS-H50-6AXIS CNC horizontal hobbing machine is an 8-axis CNC machine tool. Mainly used for shaft tooth processing, as well as high efficiency, high precision, high-volume processing of small modulus spur gears, helical gears, through numerical control technology to achieve drum gear processing and small angle cylindrical bevel gear processing, can also be used radial method of processing turbine.

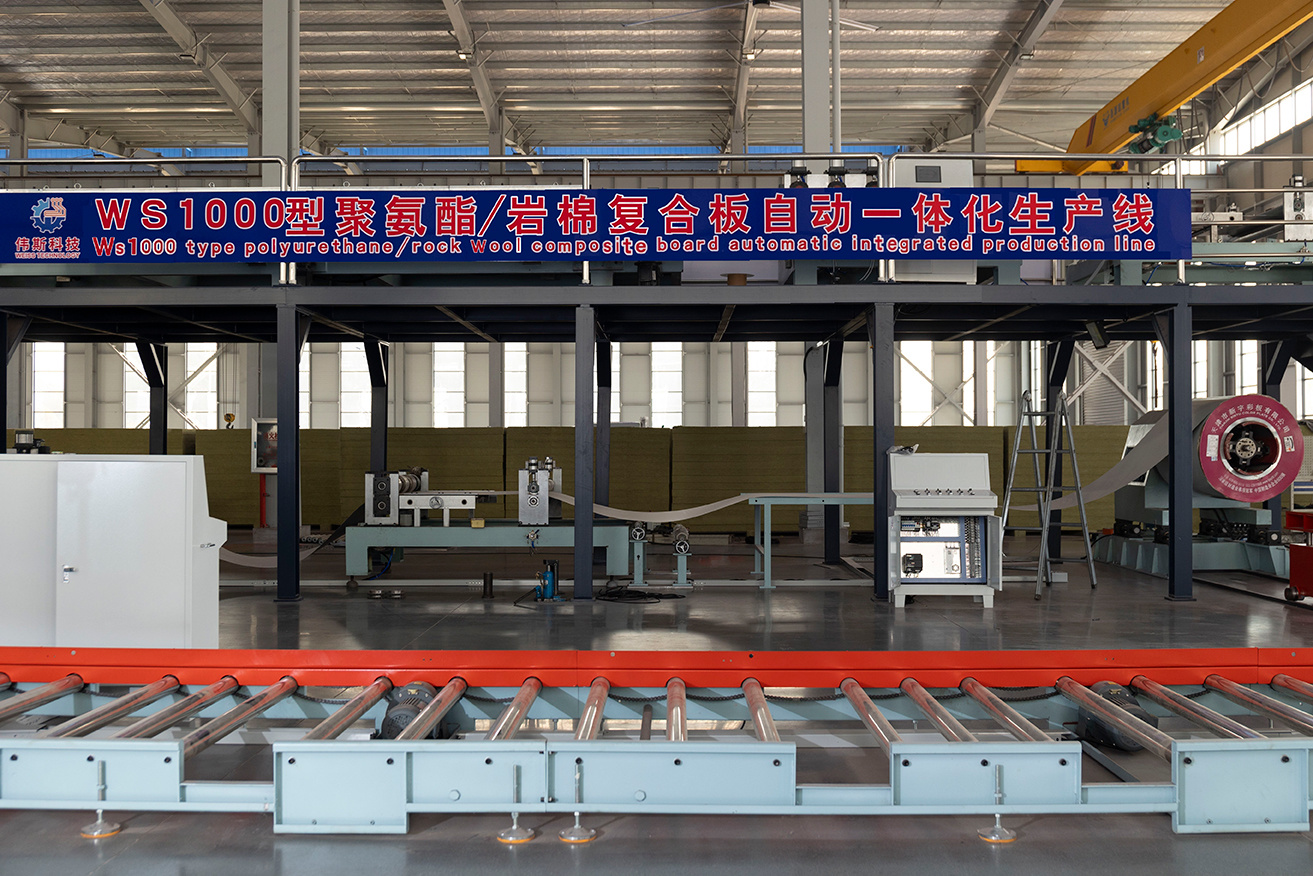

Polyurethane/rock wool composite board production line

-

Unwinding system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Upper bead roller system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Upper forming system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Lower forming system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Forming System

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Rock Wool Upper and Lower Lifting Strip System

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

90 ° flip system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Central control room system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Rock wool discharge system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

PU foaming, spraying, edge sealing foaming system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Polyurethane/rock wool board automatic production line

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Cutting system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Palletizing system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Packing system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Polyurethane/rock wool composite board automatic integration production line

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

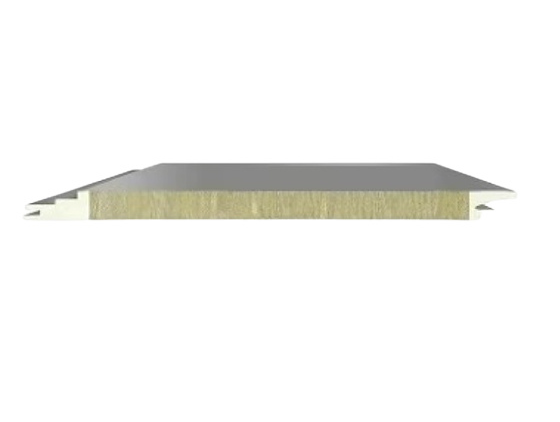

Polyurethane/rock wool sandwich panel

New fireproof rock wool/glass silk wool wall sandwich panel

-

Rock wool wall sandwich panel-reinforced

Polyurethane interface edge sealing, the middle of the rock wool core material, effectively the rock wool incombustibility, high temperature resistance and polyurethane insulation, firmness better combined together. The length can reach 24 meters or more. Performance characteristics: good sound absorption, low thermal conductivity, good load resistance, high bending strength, no water absorption, no decay, high flame retardancy, large temperature range, convenient installation.

-

Rock wool wall sandwich panel-plane

Polyurethane interface edge sealing, the middle of the rock wool core material, effectively the rock wool incombustibility, high temperature resistance and polyurethane insulation, firmness better combined together. The length can reach 24 meters or more. Performance characteristics: good sound absorption, low thermal conductivity, good load resistance, high bending strength, no water absorption, no decay, high flame retardancy, large temperature range, convenient installation.

-

Rock wool wall sandwich panel Board - Water Corrugation

Polyurethane interface edge sealing, the middle of the rock wool core material, effectively the rock wool incombustibility, high temperature resistance and polyurethane insulation, firmness better combined together. The length can reach 24 meters or more. Performance characteristics: good sound absorption, low thermal conductivity, good load resistance, high bending strength, no water absorption, no decay, high flame retardancy, large temperature range, convenient installation.

Spring machine

CNC spring press machine

-

CNC spring press machine

It has the advantages of a traditional mechanical compression spring cracking machine, as well as the high speed and accuracy of a modern computer-controlled servo system.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japanese imports of the same service motor.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japanese imports of the same service motor.

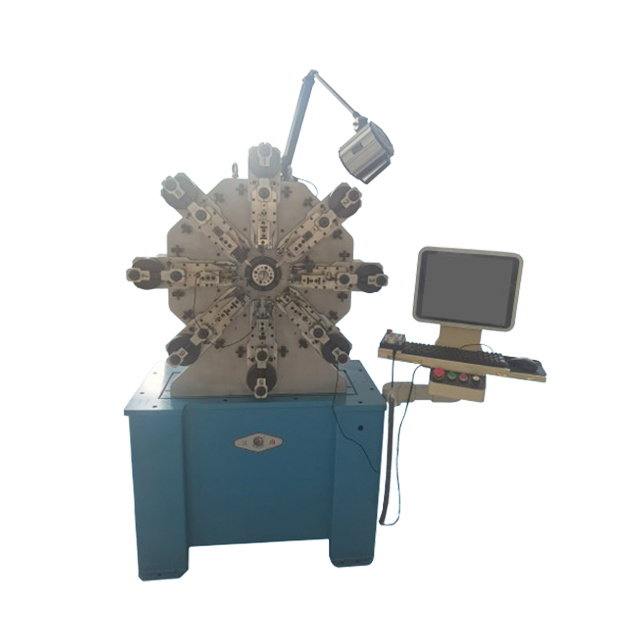

Computer spring forming machine

-

Computer universal spring forming machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

-

Computer universal spring forming machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

Computer spring transfer machine

-

Computer universal spring wire turning machine

Jiangnan independent design and process production, the country's only, and subject to patent protection.

-

Cam-free computer universal spring wire turning machine

No cam, no rocker arm design (debugging faster than the cam machine about 50%).

-

Cam-free computer universal spring wire turning machine

No cam, no rocker arm design (debugging is about 50% faster than the cam machine)

-

Cam-free computer universal spring wire turning machine

No cam, no rocker arm design (debugging is about 50% faster than the cam machine)

-

Cam-free computer universal spring wire turning machine

No cam, no rocker arm design (debugging is about 50% faster than the cam machine)

Online message

Leave your contact information to get a free product quote

Sincerely invite you to cooperate with us to create a new era of high-tech machinery!

Contact Phone

Telephone:86-19986220156 86-19986220155

email:hbweisikeji@163.com

Address: No.13, Xingye Avenue, Economic Development Zone, Yangxin County, Huangshi City, Hubei Province

Service WeChat

WeChat Public Number