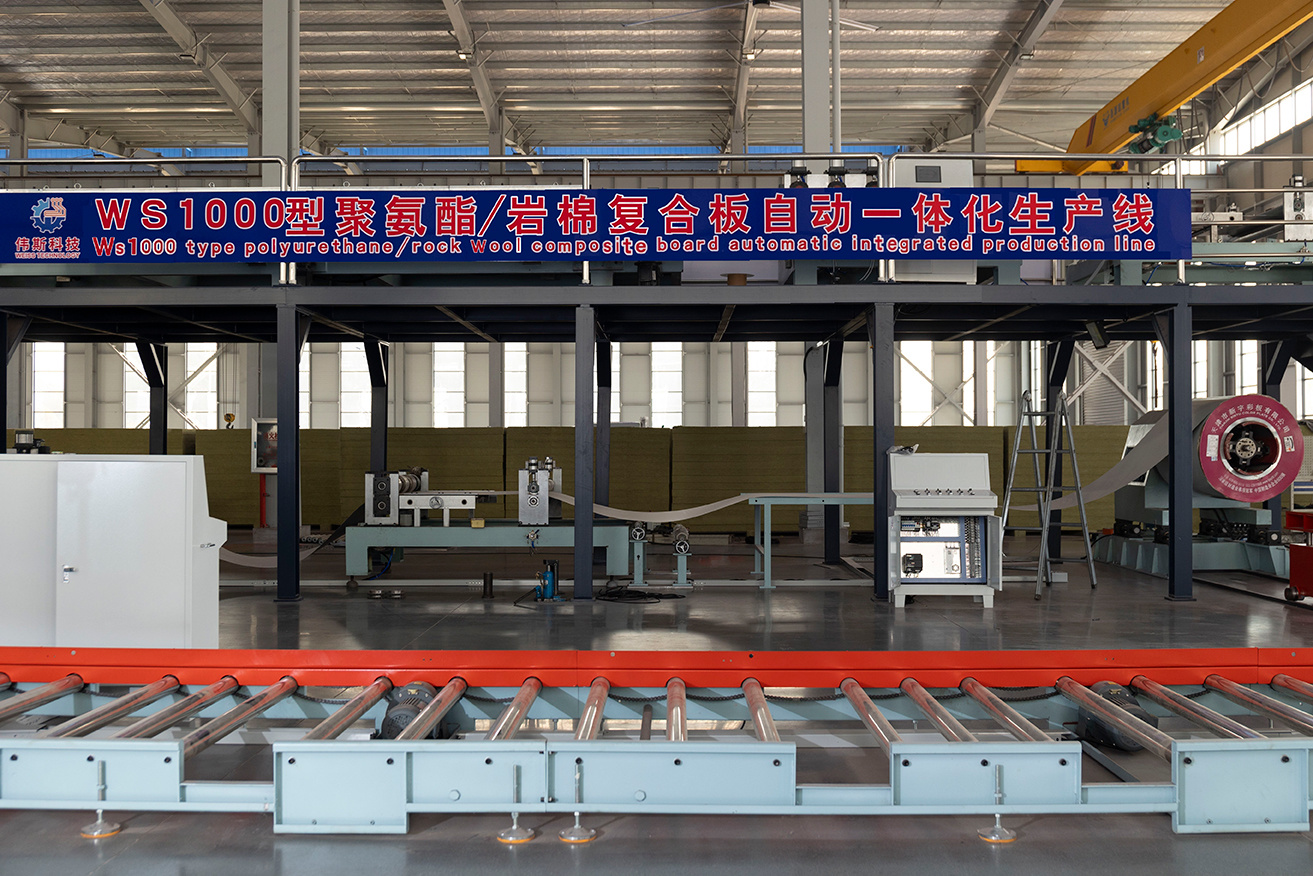

Polyurethane/rock wool composite board automatic integration production line

Product model:

Classification:

Key words:

Polyurethane/rock wool composite board production line

composite

Description

Ws100 polyurethane/rock wool composite board automatic integrated production line is an automated equipment used for producing polyurethanefrock wool composite boards,This equipment integrates an automated production line with functions such as uncoiling,laminating machine cuting,forming rock

wool,preheating,foaming,curing,cuting,cooling,stacking,and packaging.The entire line combines various technologies such as mechanical,chemical,electrical,hydraulic,pneumatic,and temperature control.

Main components:

Uncoiler;usually a sinle station,manually alined,steel welded frame,with transverse displacement achieved through wire nuts to prevent coil deviation.

Uncoiler adopts a passive type with pneumatic brake fortension control.

Tension control device:inflation control,easy to operate,used to control the tension ofthe coil material.

Preheating unpowered roller conveyor:used for conveying lower layer materials,as well as heating metal coils,aluminum foil,fiberglass cloth,non-woven

fabrics,etc.,welding frames,unpowered rollers,with protective heating devices and temperature control devices.

Foaming machine:such as BLC(R)type low-presure continuous foaming machine or PH(R/f)high-pressure foaming machine,using resin(A)material tank and curing agent(8)material tank,driven byindependentvariable frequency motors through two metering pump units,mixing each component according to the required ratio and evenly spraying between the lower steel plate or other substrates.

Mobile fabric machine:Achieve uniform arrangement of various core materials,with the main frame instaled on the base.The distance between the fabric machine and the double belt machine can be adjusted,and there is an adjusting device on the base to adiust the height.

Upper unwinding machine platform:used to support the upper laver unwindine machine,with welded steel structure and euide roller device Compression moldingmachine:for various shape processingofmetal coils.

Double track machine:completesthe online foaming and shaping of polyurethane,includingthe body,chain plate unit,lifting unit,insulation unit,and other parts,The body is ued for installation and positioning of various pats;The chain plate unit caries the core material and ensures its foaming and shaping. ensuringthe surace fiatness and thickness consistencyofthe board;Adlustthe thickness ofthe board and support the upper and lower body ofthe iftingunit.The insulation unit provides a heat source to ensure the foaming temperature and consistency ofthe core material

Non powered roler conveyor:used for plate cooling and shaping,steel welding structure,and non powered roler supportafter the double belt machine

Fixed length sawing machine:Theformed sheet metal is sawed accordingto the set size.The machine base,body,and upper movingframe are made ofwelded steel and sheet metal structures.The sawing motor is installed on the upper moving frame and is driven to move laterally by a reduction motor.The clamping device and reset device are composed ofcylinders and related components.

Working principle: Production ine achieves automated production of poyurethanelrock wool composite boards through the colaborative work of various

links. firstly,the unwinding machine unfolds the coil and maintains appropriate tension through a tension control device,preheating the non powered roller

conveyor to preheat the substrate. Then, the foaming machine mixes the polyurethane raw materials in a certain proportion and sprays them evenly on the

substrate, and the moving fabric machine evenly arranges core materials such as rock wol on the polyurethane. Next, the board enters the double track

machine,Completethe faming and shaping of polyurethane in ito form a composite board.Aferbeing cooled and shaped by an unpowered roler conveyor,

the fixed length sawing machine cuts the composite board according to the set size to obtain the final product.

Productadvantages

Strong scalability: With the addition ofunit equipmentsuch as drying boards, palletizing, and packaging at the rear,it can automatically produce varioustypes

of sandwich panels, including doublesided color panel sandwich panels, color panels, sof surace layer sandwich panels, and sof surface layer sandwich

panels.

Technical advantages: The entire production line is designed using European technical data, and after technological transformation, the cost has been

reduced. The equipment has high rigidity, strength, accuracy, and stability.

Product advantages:

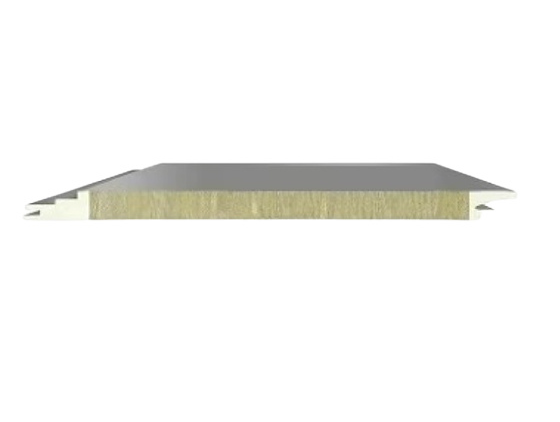

The composite panels produced by this production line are beautiful and practial, with functions such as thermal insulation, sound insulation, and fame

retardancy.

The production line uses a hot air circulation heating furnace to strictly control the temperature of polyurethane foaming and curing within the specified

range,ensuringhigh-qualitycomposite boards.

The high-presure foaming system used in the production line has accurate measurement, high stability, and minimal foating particles in the on-site

environment,ensuringthehealthof personnel.

Adopting a dual track system, the polygonal efect is solved, making the composite board surface flat, uniformin thickness, and not easily deformed.

Strong scalability ofthe production line:;Therearhas added coling board, paletizing, packaging and other unit equipment,which can automatically produce

various types ofsandwich panels such as double-sided color panel sandwich panels, color panels and soft faced sandwich panels.

This production line adopts uropean technoloey desien, with hieh inteligence, low operatingcost, hieh eauipmentrieidity,streneth,accuracy,stability,and

simple and convenientoperation.

Factory appearance

Qualification Honor

Related Products

Gear hobbing machine

Vertical gear hobbing machine

-

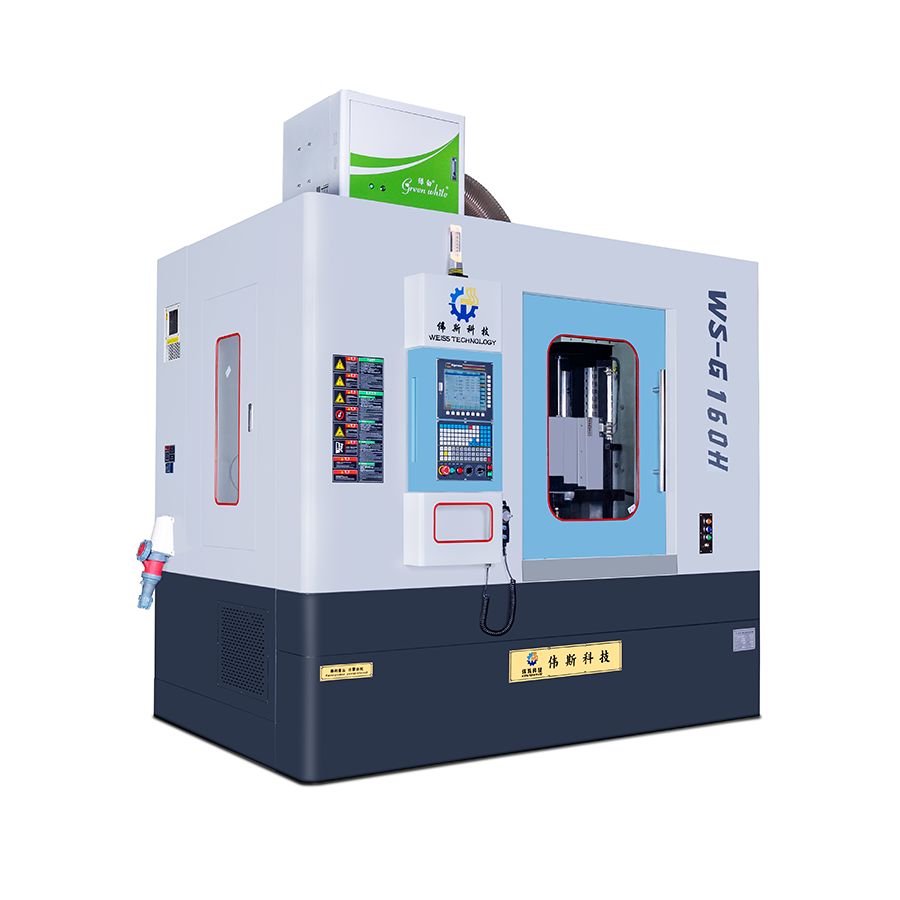

WS-G160H High-speed and efficient CNC vertical gear hobbing machine

WS-G160 high-speed and high-efficiency CNC vertical gear hobbing machine is a 6-axis 4-linkage CNC machine tool. The three numerical control linear axes are: X axis-radial feed axis; Z axis-axial feed axis; Y axis all motion axes; The three numerical control rotary axes are: C axis and worktable rotary axis; Axis B- rotary shaft of hob spindle; Axis A- frame rotary shaft. The machine tool can realize X, Z, B, C four axis linkage control.

-

WS-G260H of high speed and high efficiency direct drive CNC vertical gear hobbing machine

WS-G260H high-speed and high-efficiency direct-drive CNC vertical gear hobbing machine is a 6-axis 4-linkage CNC machine tool. The three numerical control linear axes are: X axis-radial feed axis; Z axis-axial feed axis; Y axis all motion axes; The three numerical control rotary axes are: C axis and worktable rotary axis; Axis B- rotary shaft of hob spindle; Axis A- frame rotary shaft. The machine tool can realize X, Z, B, C four axis linkage control.

-

WS-G350H of high speed and high efficiency direct drive CNC vertical gear hobbing machine

WS-G350H high-speed and high-efficiency direct-drive CNC vertical gear hobbing machine is a 6-axis 4-linkage CNC machine tool. The three numerical control linear axes are: X axis-radial feed axis; Z axis-axial feed axis; Y axis all motion axes; The three numerical control rotary axes are: C axis and worktable rotary axis; Axis B- rotary shaft of hob spindle; Axis A- frame rotary shaft. The machine tool can realize X, Z, B, C four axis linkage control.

Horizontal gear hobbing machine

-

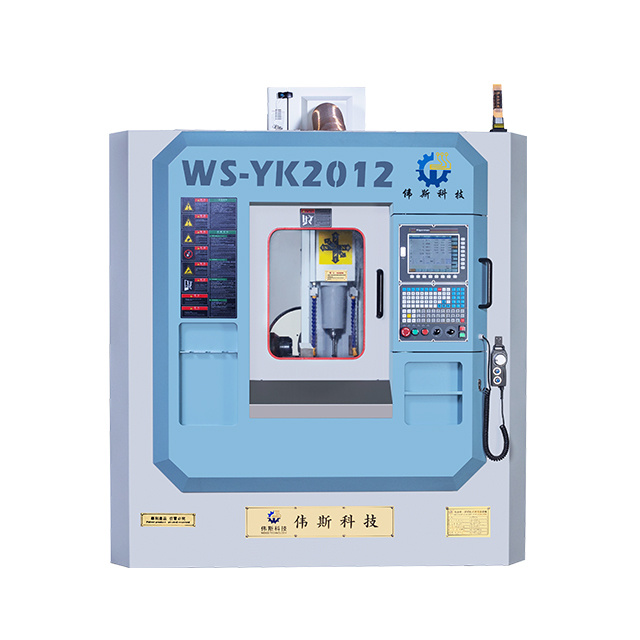

WS-YK2012 of high speed and high efficiency CNC horizontal gear hobbing machine

WS-YK2012 high-speed and high-efficiency CNC horizontal gear hobbing machine is a 7-axis 4-linkage CNC machine tool. Mainly used for shaft tooth processing, as well as high efficiency, high precision, high-volume processing of small modulus spur gears, helical gears, through numerical control technology to achieve drum gear processing and small angle cylindrical bevel gear processing, can also be used radial method of processing turbine.

-

WS-YK3016 of high speed and high efficiency CNC horizontal gear hobbing machine

WS-YK3016 high-speed and high-efficiency numerical control horizontal gear hobbing machine is a 7-axis and 4-linkage machine tool. The numerical control system uses a Higerman control system. The rotary shaft (B axis) of the cutter spindle is directly driven by a built-in direct drive motor. It is a machine tool specially developed for high-speed and high-efficiency gear high-efficiency processing. It is mainly used for processing spur cylindrical gears and helical gears with modulus m≤ 4mm, and can also be processed by radial method.

-

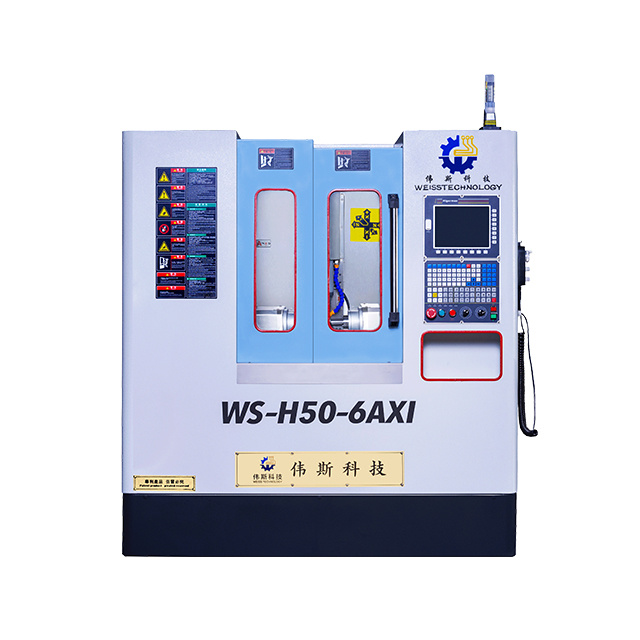

WS-H50-6AXIS of high speed and high efficiency CNC horizontal gear hobbing machine

WS-H50-6AXIS CNC horizontal hobbing machine is an 8-axis CNC machine tool. Mainly used for shaft tooth processing, as well as high efficiency, high precision, high-volume processing of small modulus spur gears, helical gears, through numerical control technology to achieve drum gear processing and small angle cylindrical bevel gear processing, can also be used radial method of processing turbine.

Polyurethane/rock wool composite board production line

-

Unwinding system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Upper bead roller system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Upper forming system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Lower forming system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Forming System

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Rock Wool Upper and Lower Lifting Strip System

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

90 ° flip system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Central control room system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Rock wool discharge system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

PU foaming, spraying, edge sealing foaming system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Polyurethane/rock wool board automatic production line

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Cutting system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Palletizing system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Packing system

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

-

Polyurethane/rock wool composite board automatic integration production line

The automatic integrated production line of polyurethane/rock wool composite panels is an automatic equipment for the production of polyurethane/rock wool composite panels.

Polyurethane/rock wool sandwich panel

New fireproof rock wool/glass silk wool wall sandwich panel

-

Rock wool wall sandwich panel-reinforced

Polyurethane interface edge sealing, the middle of the rock wool core material, effectively the rock wool incombustibility, high temperature resistance and polyurethane insulation, firmness better combined together. The length can reach 24 meters or more. Performance characteristics: good sound absorption, low thermal conductivity, good load resistance, high bending strength, no water absorption, no decay, high flame retardancy, large temperature range, convenient installation.

-

Rock wool wall sandwich panel-plane

Polyurethane interface edge sealing, the middle of the rock wool core material, effectively the rock wool incombustibility, high temperature resistance and polyurethane insulation, firmness better combined together. The length can reach 24 meters or more. Performance characteristics: good sound absorption, low thermal conductivity, good load resistance, high bending strength, no water absorption, no decay, high flame retardancy, large temperature range, convenient installation.

-

Rock wool wall sandwich panel Board - Water Corrugation

Polyurethane interface edge sealing, the middle of the rock wool core material, effectively the rock wool incombustibility, high temperature resistance and polyurethane insulation, firmness better combined together. The length can reach 24 meters or more. Performance characteristics: good sound absorption, low thermal conductivity, good load resistance, high bending strength, no water absorption, no decay, high flame retardancy, large temperature range, convenient installation.

Spring machine

CNC spring press machine

-

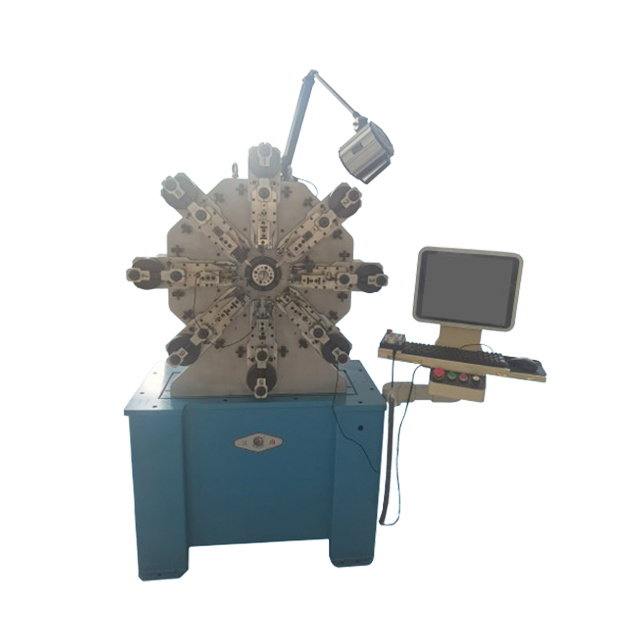

CNC spring press machine

It has the advantages of a traditional mechanical compression spring cracking machine, as well as the high speed and accuracy of a modern computer-controlled servo system.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japanese imports of the same service motor.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

-

CNC spring press machine

Using their own research and development of Jiangnan computer control system and Japanese imports of the same service motor.

Computer spring forming machine

-

Computer universal spring forming machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

-

Computer universal spring forming machine

Using their own research and development of Jiangnan computer control system and Japan imported servo motor.

Computer spring transfer machine

-

Computer universal spring wire turning machine

Jiangnan independent design and process production, the country's only, and subject to patent protection.

-

Cam-free computer universal spring wire turning machine

No cam, no rocker arm design (debugging faster than the cam machine about 50%).

-

Cam-free computer universal spring wire turning machine

No cam, no rocker arm design (debugging is about 50% faster than the cam machine)

-

Cam-free computer universal spring wire turning machine

No cam, no rocker arm design (debugging is about 50% faster than the cam machine)

-

Cam-free computer universal spring wire turning machine

No cam, no rocker arm design (debugging is about 50% faster than the cam machine)

Online message

Leave your contact information to get a free product quote

Sincerely invite you to cooperate with us to create a new era of high-tech machinery!

Contact Phone

Telephone:86-19986220156 86-19986220155

email:hbweisikeji@163.com

Address: No.13, Xingye Avenue, Economic Development Zone, Yangxin County, Huangshi City, Hubei Province

Service WeChat

WeChat Public Number