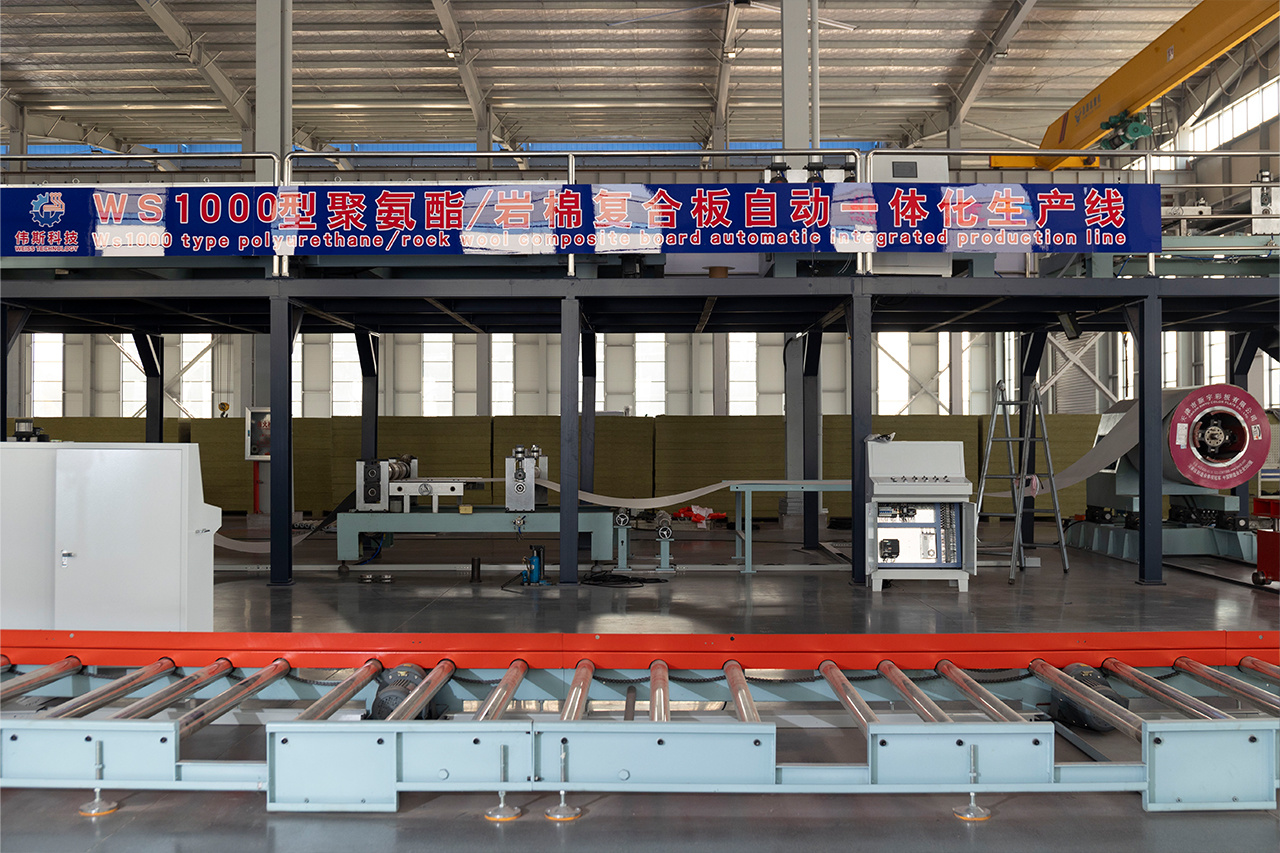

Polyurethane/rock wool board automatic production line

Release time:

2025-08-07

The Polyurethane/rock wool board automatic production line is a highly intelligent, integrated, and advanced production facility.

1. Production Efficiency

The Polyurethane/rock wool board automatic production line boasts highly efficient production capacity. It utilizes an automated control system, ensuring continuous and stable operation and significantly shortening production cycles. From raw material input to finished board output, each process is seamlessly integrated, enabling the production of large quantities of standard-compliant polyurethane/rock wool boards per hour, meeting the demands of large-scale construction projects.

2. Product Quality Assurance

High Precision

The Polyurethane/rock wool board automatic production line boasts extremely high precision during processing. Cutting and forming polyurethane and rock wool boards are controlled to extremely tight tolerances, ensuring dimensional accuracy and a perfect fit for wall installations and other construction applications.

Stable Quality

The Polyurethane/rock wool board automatic production line adheres strictly to pre-set process parameters. This ensures consistently high quality, from the polyurethane foam density, the uniform distribution of rock wool, to the overall structural strength of the boards. This stability ensures that the produced boards exhibit excellent thermal insulation, heat insulation, and fire resistance.

3. Versatility

Material Compatibility

It can produce both polyurethane boards and rock wool boards, and even composites of both, as needed. This provides construction companies with diverse options to suit different building environments and functional requirements.

Customized Production

Customized production can be tailored to specific customer requirements, such as board thickness, length, width, and surface treatment, to fully meet individual market demands.

4. Operation and Maintenance

Easy Operation

Equipped with an intuitive user interface, operators can master the production line's operations after simple training.

Easy Maintenance

The equipment's rational structural design makes key components easy to inspect and replace. The line's use of high-quality, wear-resistant, and corrosion-resistant materials reduces malfunctions and lowers maintenance costs.

The polyurethane/rock wool board automatic production line is a valuable addition to the building board production industry, significantly contributing to improved construction quality and efficiency.

More news

Sincerely invite you to cooperate with us to create a new era of high-tech machinery!

Contact Phone

Telephone:86-19986220156 86-19986220155

email:hbweisikeji@163.com

Address: No.13, Xingye Avenue, Economic Development Zone, Yangxin County, Huangshi City, Hubei Province

Service WeChat

WeChat Public Number